Winkle Press

Based on the unique process technology of up to 6 dewatering stages, the Bellmer WinklePresses achieve best yields and highest throughput capacities compared to other belt filter presses on the market.

The slowly increasing, smooth build-up of pressure up to the high pressure zone leads to optimum results.

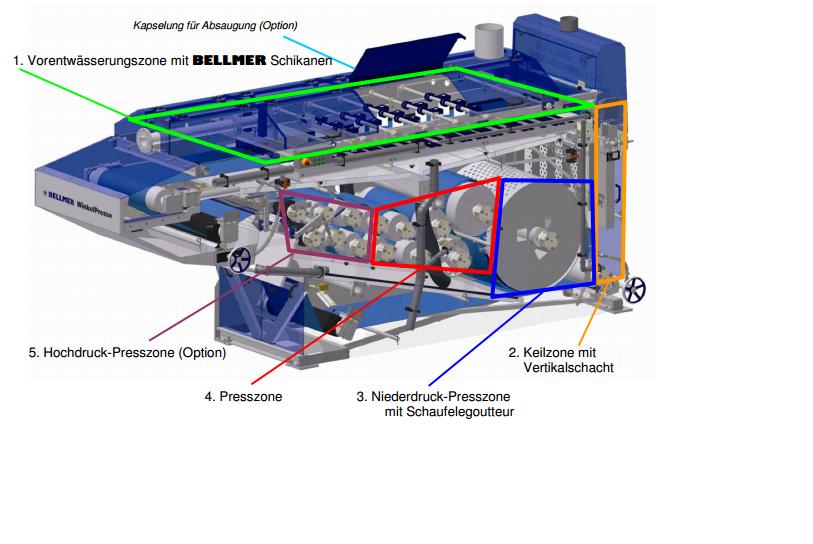

1. Horizontal gravity dewatering zone with Bellmer Chicanes

The suspension is spread over the horizontal pre-dewatering section. Major part of the filtrate drains off by gravity. The proven Bellmer chicanes essentially enhance the pre-dewatering process.

2.2. Vertical wedge dewatering zone

In the unique vertical wedge dewatering zone the two belts are gently brought together. The angle of the vertical wedge is precisely adjustable so that the pressure imposed upon the sludge is gradually and smoothly built up.

3. 3. Low pressure dewatering zone with dandy roller

The large diameter of the patented Bellmer dandy roller creates further slowly increasing pressure on the pre-thickened sludge.

4. Press zone

In S-shaped wraps the sludge cake between the upper and lower belt is directed around the press rollers, where further sludge dewatering takes place. The decreasing roller diameters impose an increasing pressure upon the sludge. Due to the Safety Precision Frame SPF, Bellmer is able to position the rollers the best possible to achieve unequalled high dry solids contents.

5. 5. High-pressure dewatering zone

To get even higher dry solids contents the press zone can be extended with an additional high-pressure dewatering zone.

6. Pressnip (Option)

The press nip, well proven in the paper industry, allows to achieve better results for certain sludges., i.e. higher cake solids contents by means of this additional linear pressure.

Your advantages:

- Low operational costs (flocculent, energy, water)

- Closed low-odour design

- High dry solids contents, thus low disposal costs

- Low manpower requirement

- Small footprint, thus low building costs

- Low maintenance costs

- Low requirement of spare and wearing parts